MAX

DIRECT+ CONDITIONING PROVIDES UNRIVALED CONSISTENCY

Patent numbers 7,014,714 and 7,611,583

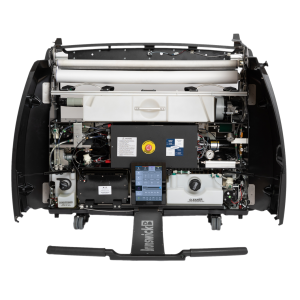

MAX features our patented Direct+ Conditioning system, which applies the oil with 39 individual injectors – one for each board. This board-by-board approach ensures precise delivery onto the lane, exactly where you want it, regardless of topography. The result is superior pattern consistency with no zigzags or multi-component transfer systems to blur the results.

With Direct+ Conditioning you know the right amount of oil is on the lane. Oil application is computer controlled by varying the injector pulse rate, not the speed of the machine.

The on-board heater warms the conditioner to 80ºF ensuring consistent application, while the buffer brush tapers for smoother transitions.

The PBA® counts on Direct+ Conditioning to provide consistent patterns for the very stringent requirements of the PBA Tour. The Direct+ Conditioning system has been used for every PBA Tour event since 2006.

FLEX POWER

MAX can be quickly switched between Lithium battery or AC/DC Power. Equipped with an on-board power supply, plugging in the power cord for a seamless transition between these options. The Lithium battery uses a smart charger to optimize battery life and performance. The charging cycle and battery use are monitored and logged through the User Interface. A buzzer will alert you if the machine is not charging after use. If the unexpected happens and the battery was not charged, your machine can be ready to go with the back-up power cord.

USER INTERFACE

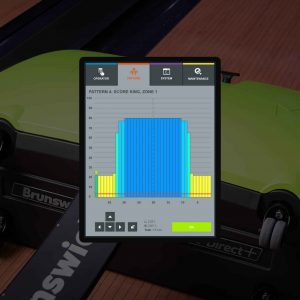

MAX features a 10.4″ Android-based touch screen tablet that is easy and intuitive to use. This is the same functional and durable tablet used in Brunswick’s SYNC™ scoring and management system. The tablet features a large screen with easy-to-navigate main menus across the top and sub menus on the left.

The tablet is also WiFi enabled, allowing for direct Internet communication between Brunswick and the lane machine. This will enhance and quicken any needed support and technical assistance. Pattern download times are also greatly improved.

Predictive analytics are included in the software allowing the user to quickly check specific parameters to ensure the machine is functioning at maximum performance and efficiency.

CONTAMINATION SENSOR

Patent Pending

MAX features a patent-pending sensor system that alerts the user when cleaner has entered the conditioner tank. Once cleaner is introduced into the machine’s system, a complete system purge is required. This sensor won’t allow the cleaner to leave the conditioning tank by automatically shutting down the machine and providing an error message. The conditioner tank can then be cleaned without adversely affecting other components in the conditioning system.

CLEANING SYSTEM

The cleaning squeegee has been engineered with ease of adjustment as a key feature. This ensures the appropriate amount of contact with the lane resulting in superior lane cleaning.

A cleaner pressure sensor monitors the cleaning pressure and generates an error message if the pressure becomes too high or too low, allowing for a quick and easy fix.

SUPERIOR PATTERN CONTROL AND MANAGEMENT SOFTWARE

MAX comes pre-programmed with high-performance conditioner patterns that can be graphically display and easily customized. Paired with the Brunswick Pattern Manager software it is easy to create your own pattern library and transfer patterns to the machine as well as make backups of the machine log files and data.

The Brunswick Pattern Manager is a program developed specifically for Direct+ Technology users. It allows you to easily manage your patterns and download them to your lane machine. Included in the Pattern Manager is the Pattern Editor which allows you to create new or edit existing patterns. The log files enable you to see how the lane machine is being used each day. Patterns can be downloaded from the Brunswick Pattern Library to your PC for use in your Brunswick MAX lane machine

QUALITY IN THE DETAILS

A single ergonomic button is conveniently located on the handle for ease-of-use. Multiple speed sensors ensure speed consistency. A very robust electronic enclosure contains connections and relays strong enough to withstand the constant demands of daily lane maintenance. The on-board heater promotes consistent oil flow while the buffer brush tapers the pattern for smoother transitions.

COVERS

The MAX covers are a vacuum formed polymer providing exceptional durability and scratch resistance. Stiff enough to provide needed durability but flexible enough to withstand impacts. They are securely latched ensuring safe and

easy transport.

The color goes throughout the cover minimizing the visibility of any scratches. Available in two color options – Black and Electric Green.

MADE IN THE USA

The MAX lane machine was engineered by Brunswick’s team of experienced engineers and technicians at the world headquarters in Muskegon, Michigan. Assembly, final quality checks and shipping also occur at this location.